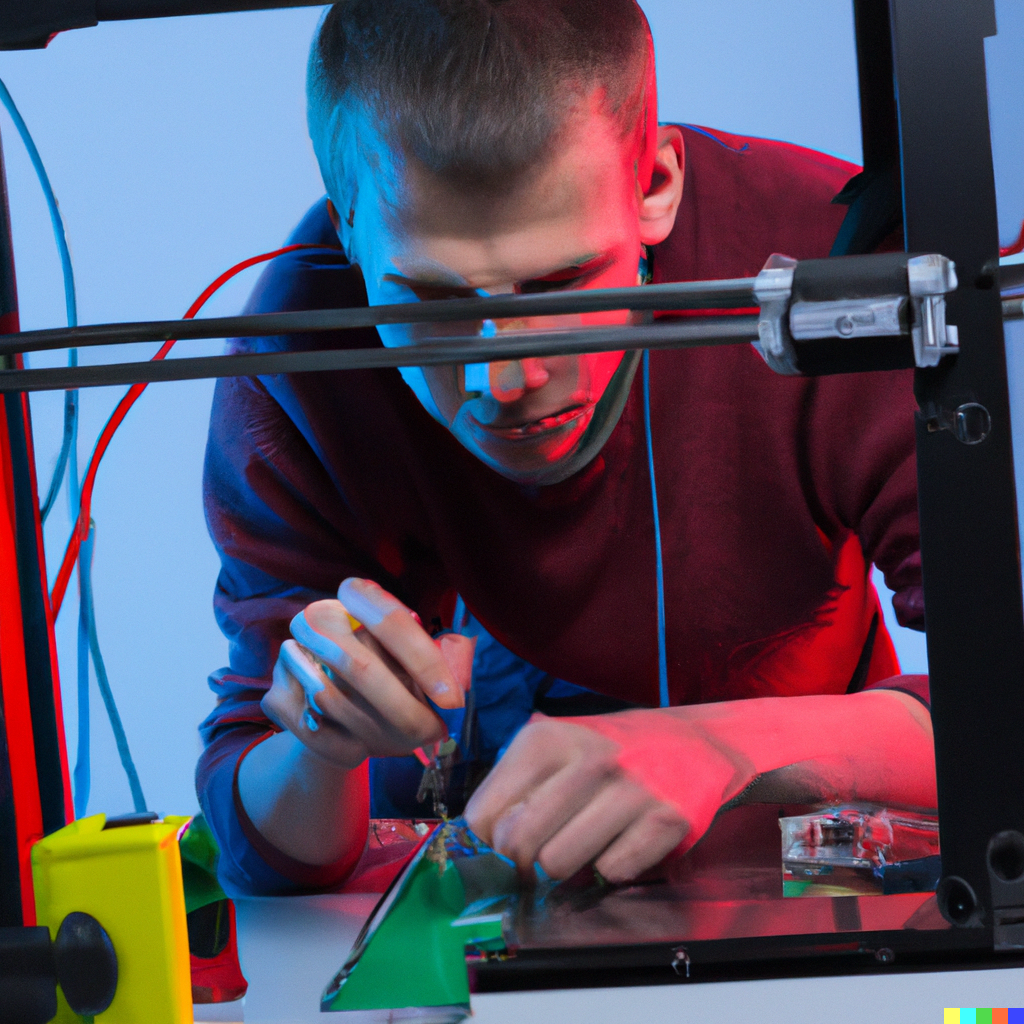

The Evolution of 3D Printing: From Novelty to Necessity

3D printing, once the stuff of science fiction, has morphed over the years from a niche interest to a game-changing technology that holds promise for industries far and wide. This revolutionary process, formally known as additive manufacturing, has transformed how we produce objects, from simple tools to complex machine components and even human organs. Let’s embark on a journey to understand the evolution of 3D printing and gauge how far it’s come.

The Humble Beginnings

The idea of 3D printing can be traced back to the 1980s. The first patent related to the process was filed by Dr. Hideo Kodama in 1980. However, it was Chuck Hull who, in 1984, successfully developed the first-ever 3D printer that used a technique known as stereolithography. This process involved using UV lasers to solidify photopolymer, a type of plastic that changes properties when exposed to light, to create 3D objects layer by layer.

The 1990s: Diversification and Expansion

During the 1990s, the field of 3D printing saw diversification in terms of techniques. Technologies like Fused Deposition Modeling (FDM), where plastic is melted and extruded layer by layer, and Selective Laser Sintering (SLS), where lasers are used to fuse powder-based materials, emerged. This decade also witnessed the rise of the first commercially available 3D printers, although they remained expensive and primarily within the realm of industries and specialized institutions.

The 21st Century Boom

The 2000s marked a turning point for 3D printing. As patents expired and technology advanced, the cost of printers dropped, making them more accessible to researchers, small businesses, and hobbyists. Additionally, the range of materials expanded beyond plastics to metals, ceramics, and even biomaterials.

By the 2010s, 3D printing’s potential was being realized in various sectors:

- Medical: Bio-printers emerged, aiming to produce tissues and organs. Custom prosthetics, dental implants, and even pills were 3D printed to cater to individual needs.

- Automotive and Aerospace: Industries leveraged 3D printing to manufacture complex parts, optimize supply chains, and reduce waste.

- Fashion and Art: Designers began experimenting with 3D-printed garments, shoes, and jewelry, leading to innovative and unique creations.

- Construction: Companies started to explore 3D printing for creating building components and even entire structures in a fraction of the traditional construction time.

The Current Landscape and Future Prospects

As of now, 3D printing has proven itself as a vital tool in rapid prototyping, enabling industries to turn ideas into tangible prototypes quickly. During the COVID-19 pandemic, the technology showcased its prowess, with countries utilizing it to swiftly produce medical equipment in response to shortages.

Looking forward, the horizons of 3D printing seem boundless:

- Sustainability: With its additive nature, 3D printing reduces waste, making manufacturing processes more sustainable.

- Space Exploration: NASA and other space agencies are exploring 3D printing to create tools and habitats for space missions, leveraging materials available on the moon or Mars.

- Personalized Medicine: The dream of printing fully functional organs tailored to individual patients might soon be a reality, drastically reducing transplant waiting times.

Conclusion

From its conceptual stages in the 1980s to its expansive applications today, 3D printing has traveled a remarkable journey. Its trajectory indicates not only its versatile applications but also its potential to redefine the future of manufacturing, medicine, art, and beyond. As the technology continues to mature and evolve, one thing is clear: 3D printing is not just a passing trend; it’s a transformative tool shaping our tomorrow.